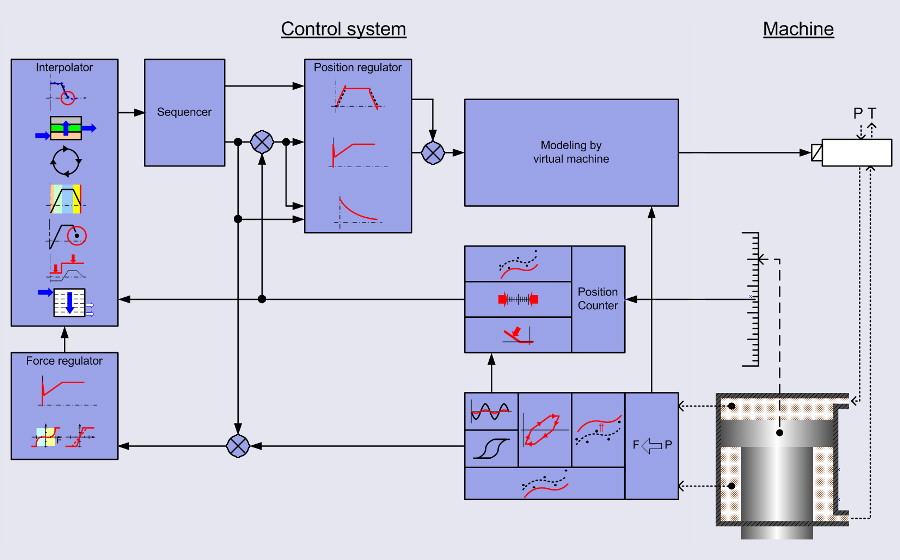

The control of precise and dynamic hydraulic axes requires special algorithms based on a powerful predictive system.

The solutions imagined and developed by EASYsa drives presses from 2 to 4000 tons, used in tooling, in cutting and hot forging.

Machines equipped with these functions perform with precision of micrometers in blank mode, a high dynamics and an impressive stability over time.

The recording of important data allows both to track the evolution of a real-time cycle and comparing with other results previously obtained.